Time:2025-09-30

Sapphire glass, as a high-performance optical material, has been widely used in various fields due to its optical transmittance range. The chemical composition of sapphire is alpha alumina (Al ₂ O3), which has a single crystal structure that endows it with excellent optical properties. In the visible light range (380-780nm), the transmittance of sapphire glass can reach over 85%, and some high-quality products can even reach over 90%. This high transmittance characteristic makes it an ideal choice for optical instruments, precision measuring equipment, and consumer electronics products.

Sapphire glass exhibits a wide transmission range from ultraviolet to infrared wavelengths. In the ultraviolet band, the transmittance significantly increases from 200nm and can reach around 80% at 250nm. This characteristic makes it of great application value in ultraviolet optical systems. In the infrared band, the transmission range can be extended to 5500nm, and it can still maintain a high transmittance in the 3000-5000nm band, making it a high-quality choice for infrared optical window materials. It is worth noting that sapphire glass has an absorption peak near 2800nm, which is a characteristic absorption caused by lattice vibration and requires special attention in practical applications.

The optical properties of sapphire glass are closely related to its preparation process. Sapphire crystals grown by heat exchange method (HEM) or Czochralski method (CZ) have better optical uniformity and higher transmittance. During the processing, precision polishing and special coating techniques can further enhance its optical performance. For example, by depositing an anti reflective film layer, the transmittance of sapphire glass in the visible light band can be increased to over 95%. This optimization process is particularly important in applications such as camera lenses, laser systems, and optical sensors.

The optical performance in harsh environments is another significant advantage of sapphire glass. It can maintain stable optical transmittance in the temperature range of -200 ℃ to 1000 ℃, which makes it suitable for special environments such as aerospace, deep space exploration, and high-temperature industrial testing. At a high temperature of 500 ℃, the transmittance only decreases by about 2-3%, which is much better than ordinary optical glass. In addition, it also has excellent radiation resistance and can maintain good optical performance in high-energy radiation environments.

Optical anisotropy is another important characteristic of sapphire. As a uniaxial crystal, sapphire exhibits different refractive indices for light with different polarization directions. In the ordinary light (o-light) direction, the refractive index is about 1.768; In the direction of extraordinary light (e light), the refractive index is about 1.760. This birefringence property has special application value in polarized optical devices, but it also needs to be fully considered in the design of optical systems. By accurately controlling the crystal orientation, the performance of sapphire optical components can be optimized in different application scenarios.

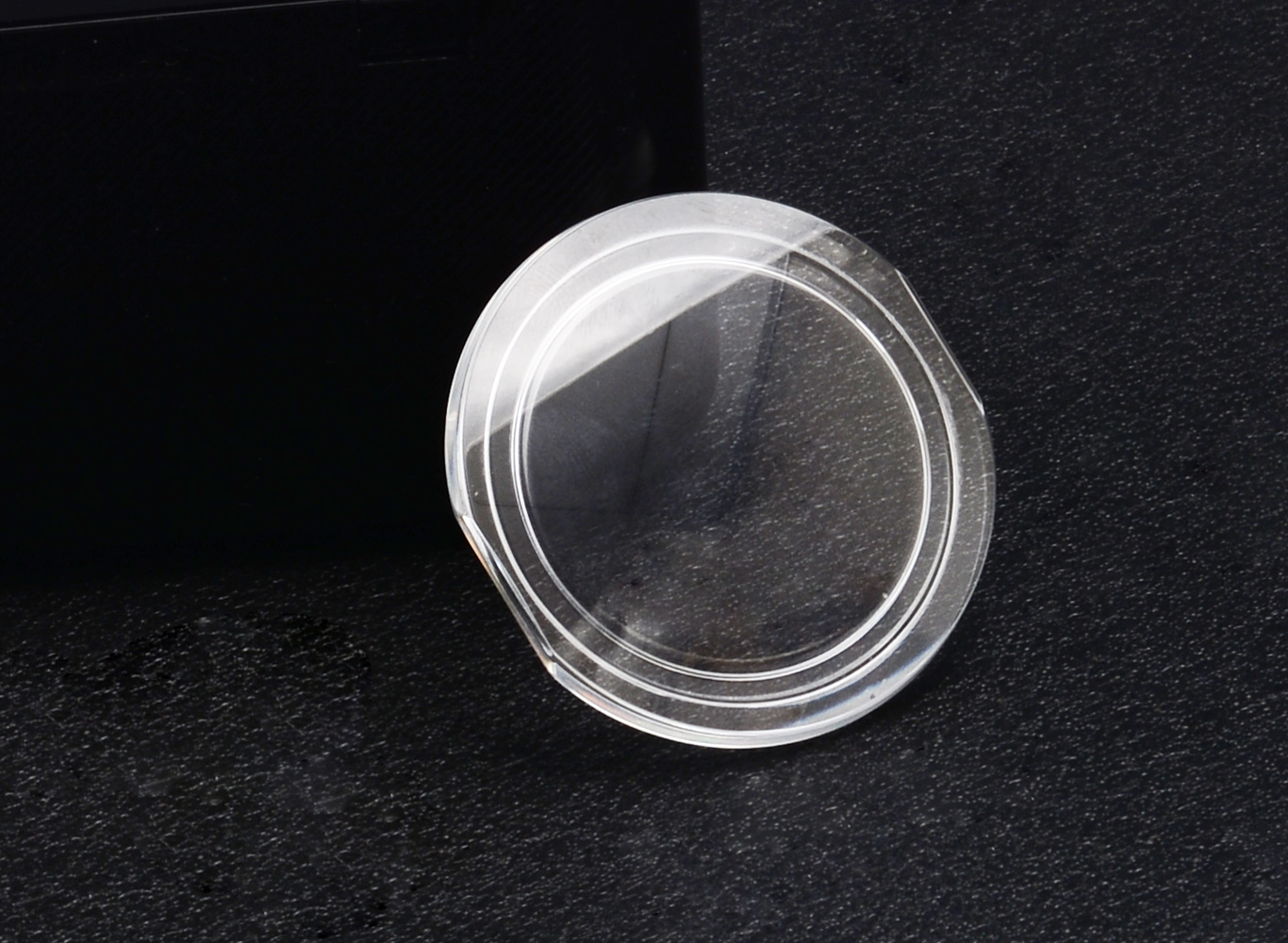

In the field of consumer electronics, it is widely used in camera protection lenses for smartphones and watch mirrors due to its excellent wear resistance and high transmittance. It is worth noting that although sapphire glass has a high surface hardness, its fracture toughness is relatively low. In practical applications, it is necessary to design the product structure reasonably to avoid brittle fracture.

In the field of laser technology, the wide transmission band makes it an ideal window material for various lasers. From ultraviolet excimer lasers to mid infrared lasers, sapphire windows can provide stable optical performance. Especially in high-power laser systems, the high thermal conductivity (about 40W/m · K) and low absorption coefficient (<0.1%/cm) of sapphire glass enable it to withstand extremely high power densities without being easily damaged.

Sapphire glass also exhibits unique advantages in the manufacturing of special optical components. Through precision machining technology, various complex shaped sapphire optical components can be manufactured, such as non spherical lenses, prisms, and irregular windows. Especially in ultraviolet lithography systems and extreme ultraviolet optical systems, sapphire components are highly favored due to their high transmittance and low fluorescence characteristics in the deep ultraviolet band.

In the field of medical equipment, sapphire glass's high transmittance and biocompatibility make it a key material for endoscopes, laser surgical instruments, and medical sensors. Especially in advanced medical imaging technologies such as infrared thermography and optical coherence tomography (OCT), sapphire optical components can provide clear image quality. Experimental results have shown that medical devices using sapphire windows can achieve higher signal-to-noise ratios and more accurate diagnostic results.

The optical performance testing of sapphire glass requires professional methods and equipment, and common testing indicators include spectral transmittance, refractive index uniformity, birefringence distribution, and surface smoothness. The use of a spectrophotometer can accurately measure its transmittance curve in various bands, while a laser interferometer can be used to evaluate its optical uniformity. In practical applications, it is also necessary to consider the impact of environmental factors such as temperature, humidity, and mechanical stress on optical performance and conduct environmental adaptability testing.

Sapphire glass occupies an important position in the field of modern optics due to its wide range of optical transmittance, excellent environmental stability, and mechanical properties. Sapphire glass plays a crucial role in everyday consumer electronics, scientific instruments, medical equipment, and space optical systems.

Tel

Mobile phone

Customer service

TOP