Time:2025-09-15

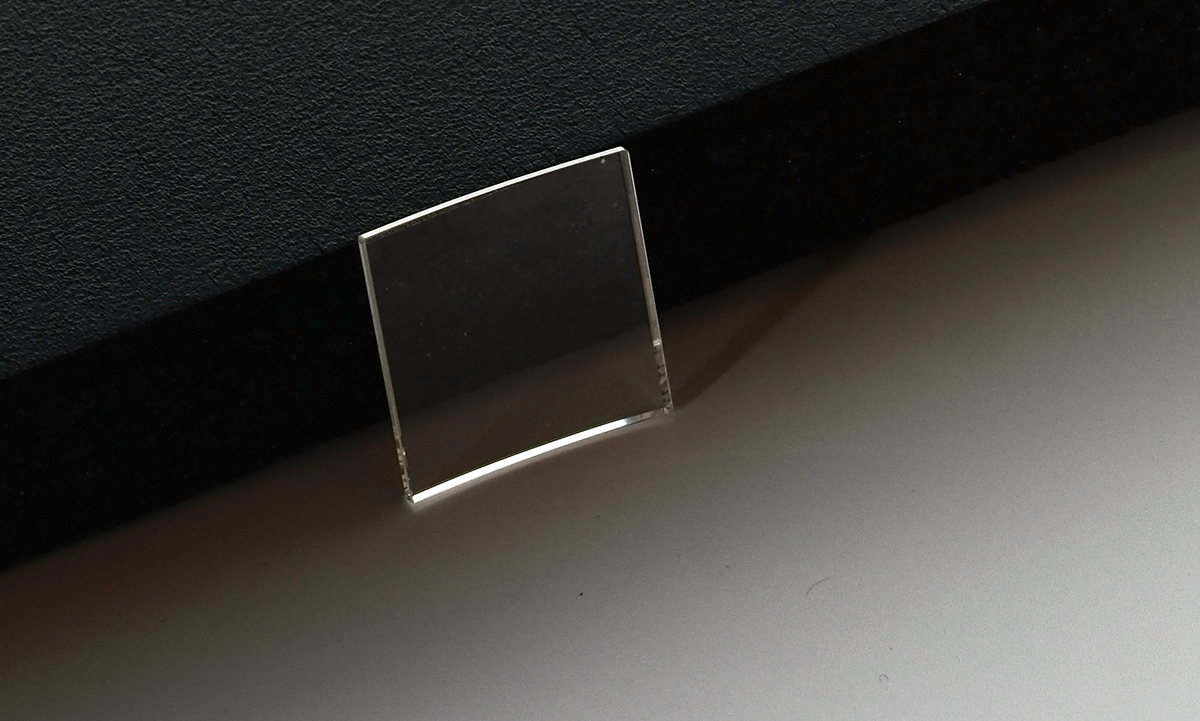

Sapphire glass, as a special material with high hardness and transparency, is increasingly widely used in fields such as smartphone screens, watch mirrors, and optical instruments. However, its Mohs hardness of 9 makes cutting a challenge in the manufacturing process. This article will explore the physical properties and mainstream cutting techniques of sapphire glass, presenting readers with the processing of this special material.

1、 Physical characteristics and cutting difficulties

Sapphire glass is not glass in the traditional sense, but an artificial crystal grown from high-purity alumina (Al ₂ O3) single crystals. The physical characteristics bring about a processing paradox: the diamond cutting wheel used in conventional glass cutting has a sharp drop in efficiency on sapphire materials, and the tool wear rate is accelerated, and microcracks are prone to propagate during the cutting process.

2、 Comparative analysis of mainstream cutting technologies

At present, mature sapphire processing technologies in the industry are mainly divided into three categories, each with its own advantages and disadvantages:

1. Laser invisible cutting technology

Using a picosecond laser with a wavelength of 1064nm, a modified layer is formed inside the material by focusing the beam. Its core advantage lies in non-contact machining, which avoids mechanical stress and is particularly suitable for precision cutting of micro components.

2. Diamond multi wire saw cutting

Drawing inspiration from semiconductor wafer processing technology, a diamond wire saw with a diameter of 0.12mm is used in conjunction with silicon carbide grinding fluid. This technology has a cost-effective advantage in the processing of large-sized sapphire substrates (such as 4-inch wafers), and the processing time for a single piece can be controlled within 30 minutes.

3. Water guided laser cutting

By coupling a laser beam into a high-pressure water column with a diameter of 50 μ m, this method combines the high precision of laser with the cooling effect of water flow. It can reduce the cutting heat affected zone to below 3 μ m, making it suitable for scenarios such as endoscopes that require strict edge quality. However, the processing efficiency is difficult to meet the requirements of large-scale production.

The paradigm shift of sapphire glass cutting technology from mechanical processing to optoelectronic composite processing, and the application of intelligent cutting equipment is changing the traditional processing mode. By introducing machine vision and artificial intelligence algorithms, the cutting system can monitor the material status in real time and automatically adjust parameters to optimize the processing effect.

Tel

Mobile phone

Customer service

TOP