Time:2025-09-04

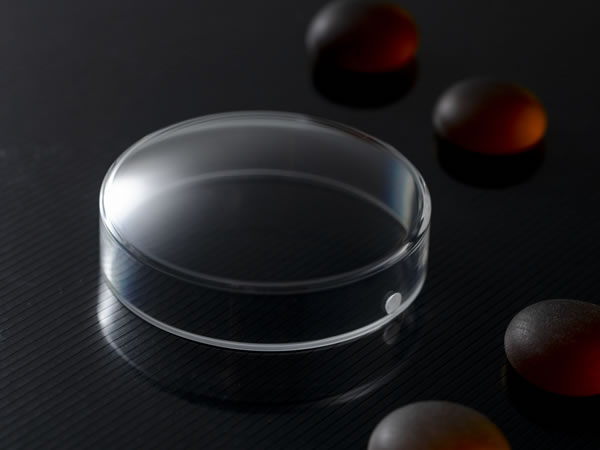

Sapphire lenses are increasingly being used in high-temperature environments due to their physical and chemical properties. Sapphire (α - Al ₂ O3) is a single crystal aluminum oxide material with high hardness, high melting point (about 2053 ℃), excellent heat resistance, and chemical stability, making it an ideal choice for optical components in harsh environments. The following analysis will focus on material properties, high-temperature application scenarios, and other aspects.

1、 Material characteristics and high-temperature adaptability

1. Thermal stability

Sapphire has a low coefficient of thermal expansion (5.3 × 10 ⁻⁶/K) and is not easily deformed at high temperatures, maintaining the stability of its optical properties. For example, in an environment of 1000 ℃, its refractive index changes by less than 0.1%, which is much better than ordinary glass or quartz materials.

2. Heat shock resistance

Sapphire has outstanding thermal shock resistance and can withstand rapid temperature changes (such as sudden rise from room temperature to 800 ℃ and then rapid cooling to -200 ℃). This characteristic makes it suitable for observation windows during spacecraft re-entry into the atmosphere or for high temperature industrial furnaces.

3. Chemical inertness

In high-temperature corrosive environments such as acidic gases or molten metals, sapphire hardly reacts with most chemicals. For example, in semiconductor manufacturing, sapphire lenses can be used as observation windows for etching machines, resistant to plasma and strong acid environments.

2、 Typical application scenarios in high-temperature environments

1. Aerospace field

-Engine monitoring system: The temperature of the combustion chamber of the jet engine can reach over 1500 ℃, and the sapphire lens serves as a protective window for the infrared sensor, which can monitor combustion efficiency and faults in real time.

2. Industrial high-temperature equipment

-Steel smelting: The infrared thermometer of the continuous casting machine needs to monitor the temperature of the molten steel through high-temperature slag (about 1600 ℃), and the transmittance (80% -90% @ 3-5 μ m band) and slag splash resistance of sapphire lenses are key.

-Glass manufacturing: In the float glass production line, sapphire windows are used to observe the flatness of the glass liquid in the tin bath, avoiding tin vapor pollution of the optical surface.

3. Semiconductor and Laser Technology

-Lithography machine lens: The optical system of extreme ultraviolet (EUV) lithography machines needs to operate in a vacuum high-temperature environment, and the low absorption rate of sapphire lenses (<0.1% @ 13.5nm) can reduce energy loss.

-High power laser: The output window of CO ₂ laser needs to withstand a thermal load of several kilowatts, and sapphire's high thermal conductivity (35-40 W/m · K) can effectively dissipate heat.

The application of sapphire lenses in high-temperature fields reflects the deep integration of material science and engineering requirements. With the advancement of preparation technology and the deepening of interdisciplinary collaboration, its performance boundaries will continue to break through, providing more reliable solutions for optical systems in harsh environments.

Tel

Mobile phone

Customer service

TOP