Time:2025-12-17

Monitoring and controlling process parameters are crucial in chemical production, and sapphire optical components have become the core components of chemical equipment due to their unique physical and chemical properties. Sapphire has high hardness, excellent chemical inertness, wide spectral transmission range (0.15~5.5 microns), and high temperature resistance (melting point 2053 ℃), which enable it to work stably in chemical environments, providing reliable technical support for process monitoring, safety protection, and efficiency improvement.

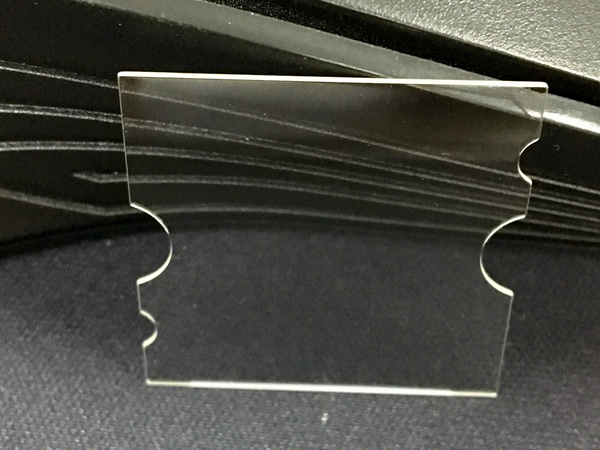

1. Window materials resistant to corrosion and high pressure environments

Chemical reactions often involve strong acids, strong bases, or high-pressure conditions, and ordinary glass or quartz windows are prone to corrosion or rupture. The chemical inertness of sapphire enables it to resist the erosion of most acids, bases, and organic solvents, while its compressive strength (up to 2 GPa) far exceeds that of ordinary optical materials. For example, in a polymerization reactor, sapphire windows can observe the status of reactants in real time, avoiding monitoring interruptions or leakage risks caused by material failure. In addition, in high-pressure pipelines of petrochemicals, sapphire sensor windows can stably transmit optical signals for a long time, ensuring the accuracy of Raman or infrared spectroscopic analysis of fluid components.

2. Real time monitoring of high-temperature processes

Many chemical processes require temperatures of hundreds or even thousands of degrees Celsius, and sapphire's high temperature resistance makes it a material for optical monitoring in high-temperature reactors. By using sapphire lenses or optical fibers, infrared thermal imagers or spectrometers can measure reaction temperature and product concentration in a non-contact manner.

3. The core carrier of laser and spectroscopy technology

Chemical process analysis relies on techniques such as laser-induced breakdown spectroscopy and Fourier transform infrared spectroscopy, and the high transparency and low fluorescence background of sapphire optical components are the basis for achieving high-precision detection through these technologies. In the wafer cleaning process of semiconductor chemistry, the sapphire lens focused ultraviolet laser can accurately remove surface impurities; In the exhaust gas treatment system, the gas analysis module composed of sapphire prisms can monitor the concentration of harmful substances such as hydrogen sulfide and nitrogen oxides online, ensuring that emissions meet standards.

4. Safety protection and explosion-proof design

Chemical equipment has high explosion-proof requirements, and sapphire's insulation and impact resistance make it an ideal choice for sensors in hazardous areas. For example, in flammable and explosive ethylene production lines, sapphire encapsulated fluorescent fiber sensors can avoid the risk of electrical sparks while accurately measuring pressure and temperature changes. In addition, the anti-wear properties of sapphire coating can extend equipment life and reduce downtime losses caused by frequent component replacement.

Sapphire optical components provide critical support for the efficient, safe, and intelligent development of the chemical industry through their durability, stability, and functionality. From reaction monitoring to emission control, from basic research to industrial scaling up, the value of this "industrial gem" will continue to be released, driving chemical technology towards greater precision.

Tel

Mobile phone

Customer service

TOP