Time:2025-11-26

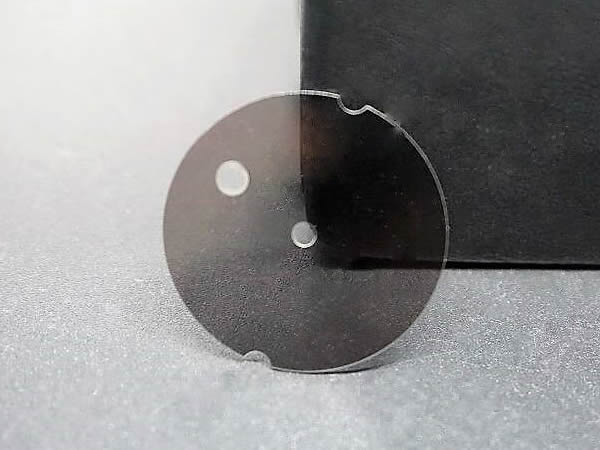

Sapphire lenses, as a high-performance optical material, are demonstrating value in multiple fields due to their physical properties. Its scratch resistance far exceeds that of ordinary glass; At the same time, it has the advantages of high light transmittance (about 85% in the visible light band), high temperature resistance (melting point 2053 ℃), and chemical stability, making it the intersection of technology and daily life.

1、 In the field of consumer electronics

The smartphone industry has taken the lead in pushing sapphire lenses from the laboratory to the mass market. Sapphire can be used to protect camera modules, allowing lenses to maintain optical clarity in harsh environments such as sand and dust. In the field of smartwatches, a sapphire trend has emerged, achieving a waterproof rating of 10ATM while maintaining a total thickness of 1.5mm. This is due to the dense crystal structure of sapphire, which has a density of 3.98g/cm ³ and can effectively block the penetration of water molecules.

2、 Industrial testing system

In high-temperature industrial scenarios, sapphire lenses exhibit astonishing environmental adaptability. The semiconductor manufacturing equipment adopts a sapphire observation window with a diameter of 200mm, which can work continuously for 3000 hours at 800 ℃ without thermal deformation. Its thermal expansion coefficient is only 5.3 × 10 ⁻⁶/℃, which is 1/8 of that of ordinary optical glass. This stability ensures accurate monitoring of the wafer processing process. The laser cutting equipment utilizes the high damage threshold of sapphire (10J/cm ² @ 1064nm) to withstand continuous irradiation of 20kW level fiber laser.

3、 The guardian of the life of medical equipment

Minimally invasive surgical robots are pushing sapphire lenses into the field of life sciences, such as dental treatment equipment that utilizes sapphire's ultraviolet transmission characteristics to develop curing lamp light guides that can output 365nm wavelength light, reducing resin curing time to 3 seconds. In vitro diagnostic equipment, sapphire flow cell becomes the core component of blood analyzer. The surface hydroxyl density is controlled at 5/nm ², effectively reducing non-specific protein adsorption.

From smartphones to industrial optical systems, the application boundaries of sapphire lenses are constantly expanding. This material, which combines ultimate physical performance and process flexibility, is redefining technical standards in multiple industries. With the advancement of heterogeneous integration, micro nano processing and other technologies, sapphire may become a strategic material platform connecting the macro and micro worlds.Tel

Mobile phone

Customer service

TOP