Time:2025-12-10

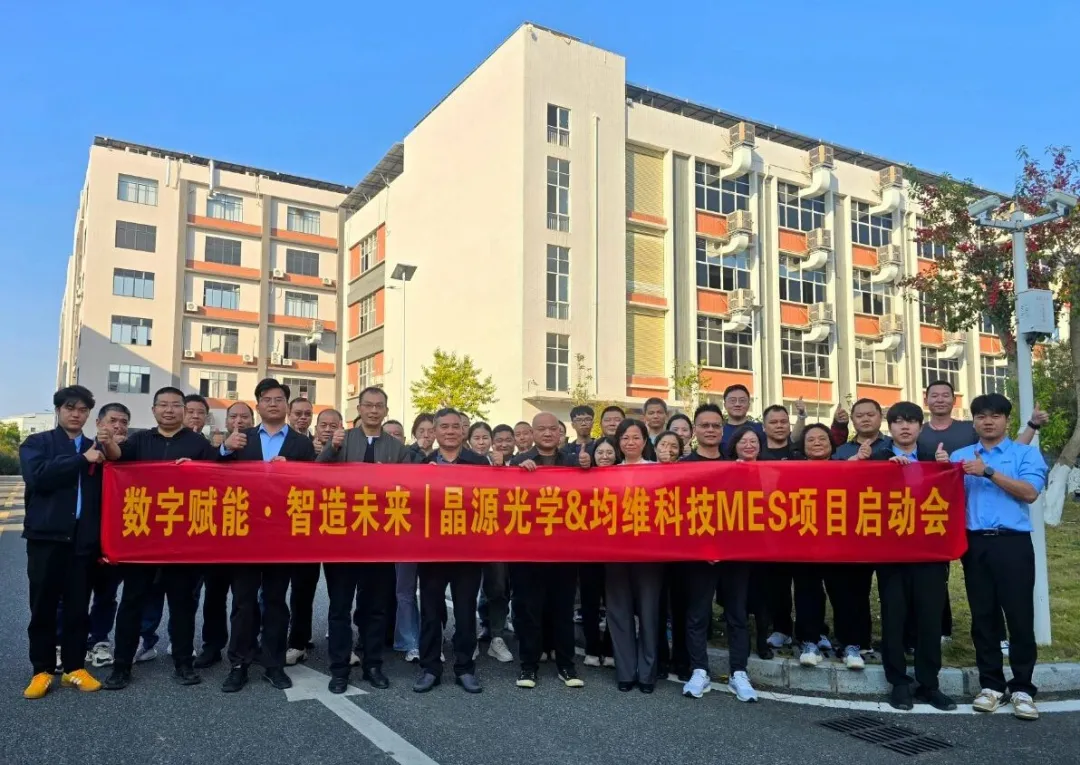

As an enterprise in the field of sapphire cover plate manufacturing, Xinyuan Company officially joined hands with industrial digital solution expert Junwei Technology to hold the MES (Manufacturing Execution System) project kickoff meeting at the Heyuan production base (Jingyuan Optics) this afternoon, marking a crucial step forward for Xinyuan Company in the transformation of production digitization and intelligence. This cooperation is not only a technological upgrade, but also a strategic initiative to build smart factories and reshape manufacturing competitiveness in the era of Industry 4.0.

As a core supplier of sapphire cover plates in high-end watches, smart wearable devices, optical instruments and other fields, Xinyuan Company has always been known for its exquisite craftsmanship and excellent quality. However, with the increasing demand for personalized products in the market, the acceleration of product iteration speed, and the improvement of industry chain collaboration requirements, the traditional production mode that relies on manual scheduling, paper-based processes, and experiential decision-making has gradually exposed pain points such as information opacity, slow response speed, difficult quality traceability, and low resource scheduling efficiency.

Under the trend of digitalization, networking, and intelligence in the global manufacturing industry, Xinyuan Company deeply realizes that only by actively embracing digital transformation and using data as a new production factor can it truly achieve cost reduction, efficiency improvement, quality improvement, and flexible manufacturing, consolidate and expand its leading advantage in the high-end sapphire processing field.

The MES project launched this time is the core project of Xinyuan Company's digital transformation. The MES system, as the "nerve center" connecting the enterprise planning layer (ERP) and workshop control layer (automation equipment), will digitally manage and monitor the entire production process of Xinyuan Company in real-time.

1. Visualize the entire process, making production clear at a glance

Through the MES system, the status and data of every process, equipment, operator, and mirror from sapphire crystal cutting, grinding, polishing, coating, cleaning to final inspection and packaging will be collected and presented in real-time. Management personnel can grasp production progress, equipment utilization, work in progress inventory, and order delivery status anytime and anywhere through kanban, achieving a leap from "fuzzy management" to "precise insight".

2. Refined process control to ensure ultimate quality

The production of sapphire watch mirrors requires extremely high process parameters, environmental cleanliness, and operational standards. The MES system solidifies key process parameter standards into the system, achieving automatic error prevention and warning. Each watch mirror will have a unique "electronic ID card" (barcode/RFID), which records its process parameters, quality inspection data, operators and other information throughout the process, forming a complete quality traceability chain. Once a quality problem occurs, it can quickly locate the link and cause, greatly improving quality control capabilities and customer trust.

3. Optimize resource scheduling to improve overall efficiency

The system uses intelligent scheduling function to comprehensively consider factors such as order priority, equipment status, material preparation, personnel skills, etc., and automatically generates efficient production plans to reduce equipment waiting and material idle time. At the same time, by analyzing equipment operation data, predicting maintenance needs, reducing unplanned downtime, and comprehensively improving equipment overall efficiency (OEE).

4. Data driven decision-making empowers management innovation

The MES system will deposit massive and authentic production data. Through the data analysis tools provided by Junwei Technology, Jingyuan Optics can deeply analyze production bottlenecks, cost composition, and quality fluctuation patterns, providing scientific basis for decision-making such as process optimization, capacity planning, and cost control, and promoting the upgrading of enterprise management from "experience driven" to "data-driven".

The launch of the MES project is just the first chapter of Xinyuan Company's blueprint for "Digital Empowerment and Intelligent Manufacturing for the Future". Looking ahead to the future, based on the real-time data gathered by MES system, it can be further extended upwards and downwards.

The wave of digitization is surging, and the intelligent future has arrived. The launch of the MES project by Xinyuan Company demonstrates its forward-looking layout and determination to innovate as an industry leader. Through this digital transformation, Xinyuan Company will not only build a more efficient, transparent, and reliable modern smart factory, but also establish core digital capabilities for future competition.

We firmly believe that under the strong driving force of the digital engine, Xinyuan Company will continue to empower global high-end brands with dazzling "sapphire" quality, and write a more brilliant chapter in the journey of "smart manufacturing for the future".

Tel

Mobile phone

Customer service

TOP